"New" Metropolitan emergency room in Oslo

"New" Metropolitan emergency room in Oslo

It was decided early on, that the new metropolitan emergency room in Oslo should be and consist of forward-looking, environmentally friendly solutions, that both provide flexibility during construction, and on the day the building is put into use.

According to Advensia - which had the responsibility of project management - the project "Oslo Metropolitan Hospital" (OSBL) has been carried out as a broad collaboration project. In the tender and contracting process, emphasis was placed on team, tools, experience and understanding of the task. The cost of the implementation was not part of the competition. Something that has given the participants an opportunity to think in new and alternative ways.

- The fact that OBSL has been carried out as a collaborative project has given us the opportunity to think outside the box and opened for testing new, modern tools. I think having to go back to the old ways will be difficult for any and every one of us,

says Peder Bogsti. Former formwork carpenter, now senior advisor and BIM specialist, in the "BIM and VDC department" at Skanska Technique.

- The fact that OBSL has been carried out as a collaborative project has given us the opportunity to think outside the box and opened for testing new, modern tools. I think having to go back to the old ways will be difficult for any and every one of us,

says Peder Bogsti. Former formwork carpenter, now senior advisor and BIM specialist, in the "BIM and VDC department" at Skanska Technique.

A long-awaited "go-to solution"

Skanska's focus on digital tools has for a long time had as its overarching goal to replace all manual IT- work with smarter software. With the aim of creating a workflow that saves time, reduces costs, increases quality and removes all types of "paper" from the process. Including post-it notes throughout the design and production- drawings for use - and trouble - on the construction site.

- If you ask me, the elegance of StreamBIM lies in the fact that everything is gathered in one place. In the self-explanatory interface you will find all the tools and aids you may need. On one and the same easy-to-navigate surface. Being able to collect as much as possible in one solution is worth its weight in gold. - says Bogsti.

Modern principles of interaction

Skanska has put in a lot of work over time to design a robust framework for planning and implementation. A framework that starts with finding out what the building will solve and what the project team must deliver to meet the identified needs. The VDC work is then built on the three pillars: Involving planning "Last Planner System" (LPS), "Integrated Concurrent Engineering" (ICE) with co-location in a "Big Room" and BIM with an associated digital interaction- platform.

- It is especially on the latter two pillars that StreamBIM has proven to be of great use. The software has allowed us to collect what previously lay on several scattered tools on one and the same surface, says Bogsti.

Uninhibited workflow

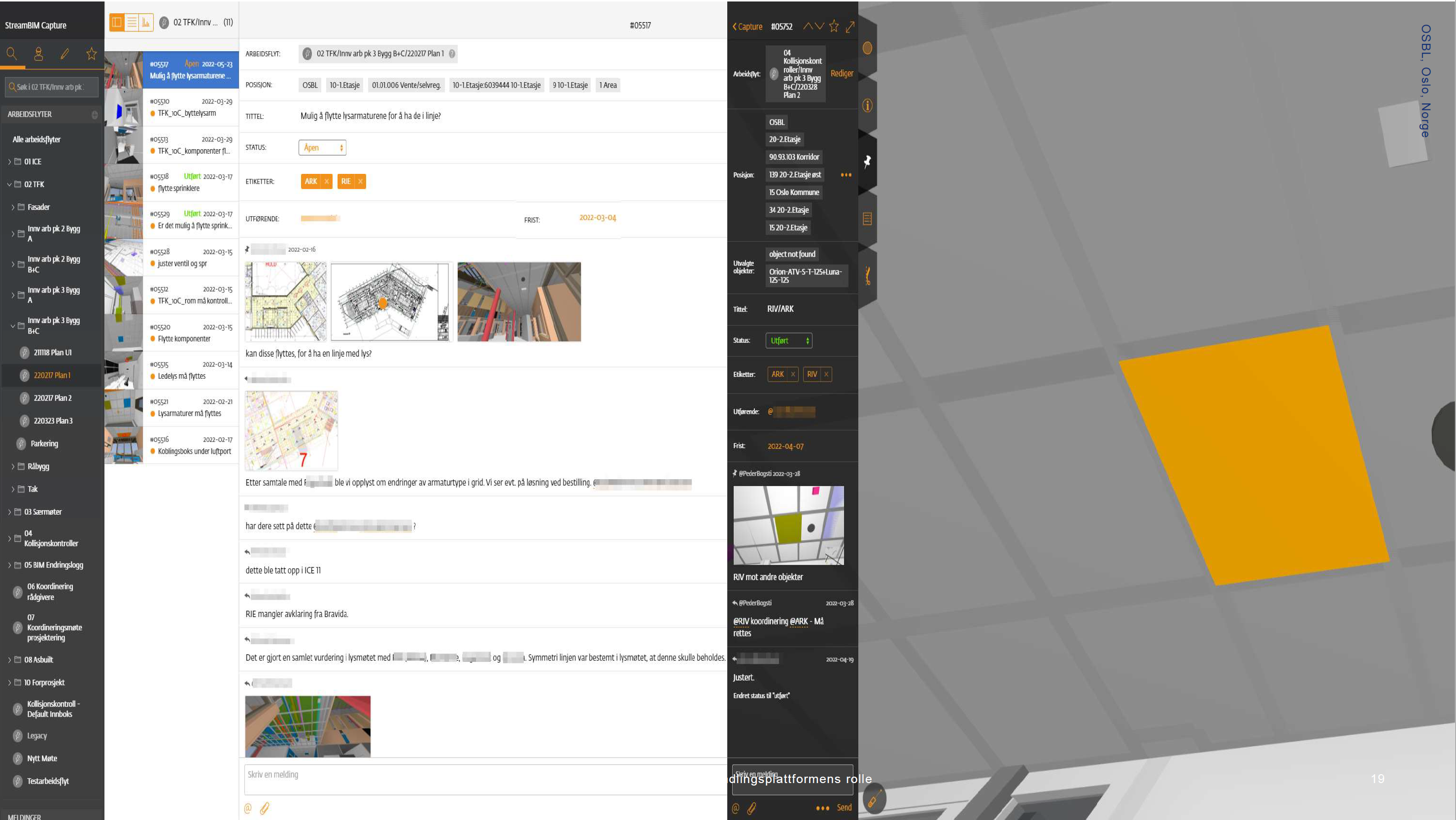

It was decided early on to move all the "minutes" and cases from the design sessions (ICE), Interdisciplinary Control (TFK) and Collision Control (KK) - into the workflow they themselves had set up in StreamBIM.

- In the past, the "minutes" from the ICE meetings have at best been recorded down in OneNote and sent to the participants by email. On this project, this is done directly in StreamBIM with "smart points" - or "cases" if you like. With it, everyone has access to updated plans and the latest decisions. And most important, who is responsible and which deadlines apply.

Full integration

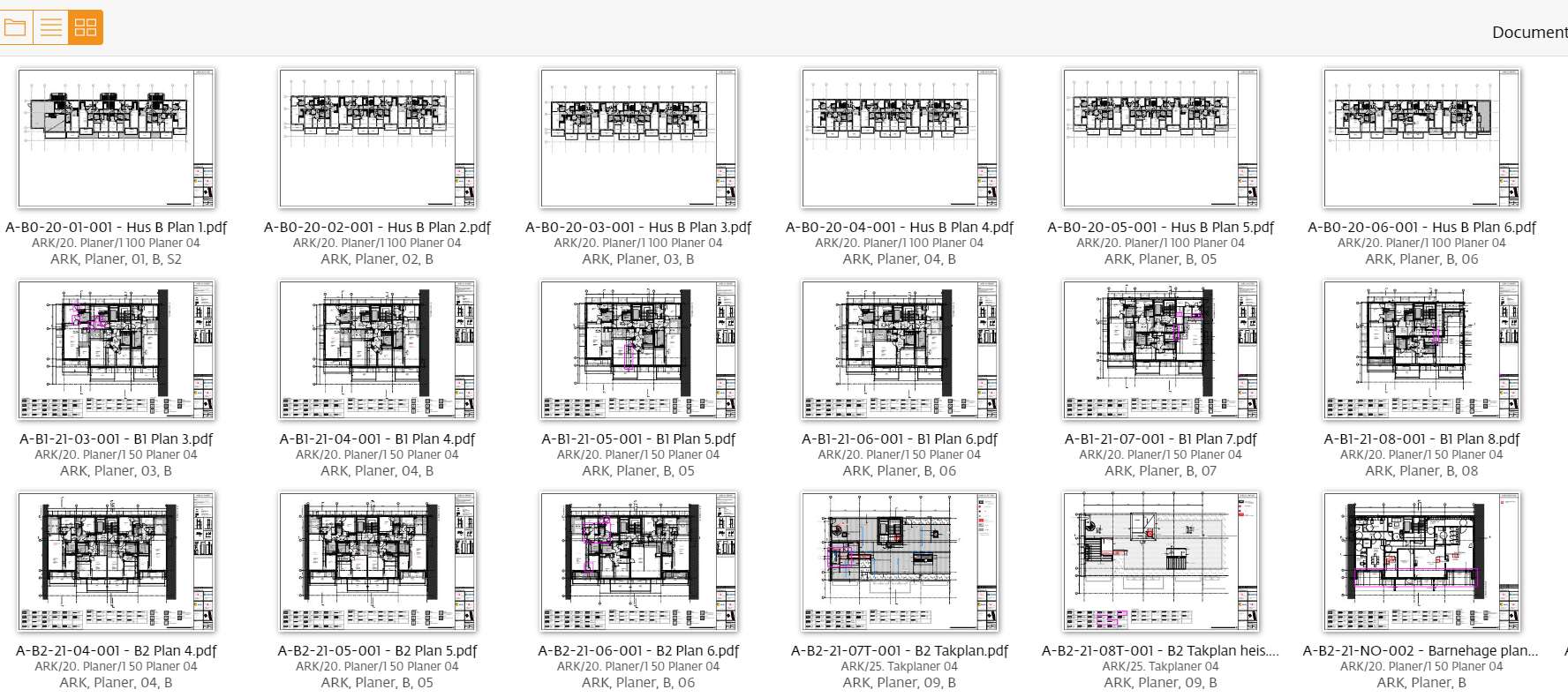

Bogsti says that the workflow also provides automatic, daily sync of drawings with attached and structured metadata. Immediately made available for building site. - Always. - Across the project. - On all surfaces. Via an agreed routine for using the interaction platform.

- We get all the points from interdisciplinary control logged. Points we have seen little of before. Because it is something the advisers "do". Usually, we get a declaration that an interdisciplinary check has been carried out. Then we run a collision check based on that. Not infrequently, it turns out to be far more errors that should have been weeded out at this stage. With StreamBIM, we get rid of this uncertainty and push errors and deficiencies back to where they belong. So that the advisers themselves become responsible for the interdisciplinary control they have already been paid to carry out.

- With StreamBIM, we get rid of this uncertainty and push errors and deficiencies back to where they belong.

So that the advisers themselves become responsible for the interdisciplinary control they have already been paid to carry out.

- With StreamBIM, we get rid of this uncertainty and push errors and deficiencies back to where they belong.

So that the advisers themselves become responsible for the interdisciplinary control they have already been paid to carry out.

Heavy progress

Via StreamBIM, you can see what the individual engineer or architect brings to the table and whether the task has been completed. All communications are grouped together under the given "case." Tagged with subjects, status, comments and history. Tags you can filter on and measure against, at an overall level, based on all the points in the workflow. So that you can see, opened and closed "cases." Or you can do it for the individual, pre-structured "package" you have defined. Simple and effective.

- In the subsequent collision check - which we carry out ourselves - the structure is exactly the same. Here we can also insert drawings, PDFs, make notes on clippings and find out where the "things" are physically located in the model. The actual collision check is usually carried out in Solibri, but I import the "cases" via. BCF, into StreamBIM and follow them exclusively there. Which is a huge improvement to the workflow, says Bogsti.

Proven effect

Bogsti says that on a given day - specifically the seventh of June 2022 - the project had a total of 1,061 issues from “Interdisciplinary Control”. Of which only three were not closed. Which corresponds to less than 0.3 percent still open. From the collision check, the team had eight of 1145 cases open on the same day. From the ICE planning meetings 29 out of a total of 451 was open.

- You may have to be a reasonable engineering geek to see the value of numbers like this. For me, however, they say on the one hand how much control this gives us, and on the other that we are definitely on track with the design. It may be perceived as a bit narrow, but I think that most engineering managers raise both their hats and eyebrows at figures like this, says Bogsti.

Make a difference in production

Bogsti says that he is of the opinion that the platform also makes a difference in production. That the model is available on all devices and that it is easy to find what you need to get your job done, where you are, when the need arises is extremely handy.

- We have more than 2,000 synced digital drawings. Which everyone can get right down to their handheld device with three or four keystrokes. Admittedly, they must have the "correct" role in relation to access control. With this, the client's and Skanska's goal of a paperless building site can be realized.

Synced "Super-drawing" to prevent printing

According to Bogsti, the best "drawing" is in the "A1" format that contain alot of information. This is a so-called "Super-drawing," which corresponds to two square meters in a size ratio of 1:50. If it - (or parts of it) - is to be printed on paper, most of the information is in such a small print that you have to use a magnifying glass to read it.

It is a problem that a large variety of out-of-date, obsolete versions of production- drawings is used around on construction sites, which is a reason why printing out drawings is not as attractive. With StreamBIM everyone has the latest updated version available digitally.

Easy access to your digital "super-drawings" on any device with StreamBIM.

Easy access to your digital "super-drawings" on any device with StreamBIM.

A project on track

Bogsti believes that StreamBIM has contributed greatly to the fact that the project has finished according to plan, and that the budgeted cost for the project is well below budget - despite an epidemic. Not least, he is happy for all the follow-up and help from the StreamBIM staff along the way.

Bogsti is also of the opinion that using the interaction platform within a framework of VDC methodology has worked surprisingly well and put the project at the center.

- The interaction platform and VDC have given us a streamlined design process. None of the people I have spoken to will return to a reality without an interaction platform, concludes Bogsti.

- - -

Learlings from the project

Traditional project- processes without StreamBIM:

- The ICE meetings are logged at best as "stupid minutes" in OneNote or similar.

- "Cases and issues" from interdisciplinary controls are handled between the subjects by e-mail with very little traceability and no transparency, which makes it difficult to know the status.

- The summary file for "issues" is typically updated once a week via the desktop version of Solibri.

- Email is the "Go-to" for most problem solving.

- Project participants have many different tools to maintain and keep track of.

- It is operated with physical drawings on site without control of versions and revisions.

Project- processes with StreamBIM:

- ICE points are stored as "cases or issues" continuously on one platform, tagged with responsible person, deadline for rectification and with precise location.

- "Cases and issues" from interdisciplinary control are added to the associated workflow for the given zone or package and are visible to all stakeholders. Which makes it easy to see if a given "issue" is being rectified or if it has already been fixed.

- Reports from the collision inspection are followed up in StreamBIM, with deadlines and responsibility for correction. The individual can easily filter on their own areas of responsibility and tasks.

- The model is updated every day and is available to everyone, on all devices at all times.

- Creating a "case" in StreamBIM is the "go-to" solution for all challenges, errors and deficiencies. Transparent and tidy.

- StreamBIM is the central information carrier and makes drawings, models and "cases" available in one and the same interface.