トータルBIM手法とデジタル建設におけるその重要性。.

ビルディング・インフォメーション・モデリング(BIM)は、北欧の建設業界では20年以上前から不可欠な要素となっていますが、その導入は設計段階に限られています。多くの(ほとんどではないにせよ)プロジェクトでは、BIMモデルは従来の2D図面を生成するために使用され、その後モデルは更新されなくなり、信頼されなくなり、積極的に使用されなくなります。.

図面とBIMの並行ワークフローは、デジタル建設の可能性をフルに発揮するための大きな障壁として繰り返し指摘されてきました。 何をやめるべきか, 新しいワークスタイルの導入だけではありません。.

BIMの採用からトータルBIMへ

北欧の建設業界のベストプラクティスに基づき、スウェーデンのイェーテボリにあるチャルマース工科大学が開発したトータルBIM手法は、この断片的なアプローチからの根本的な転換を意味します。トータルBIMは、BIMを補助ツールとして扱うのではなく、設計から建設、そしてそれ以降に至るまで、プロジェクトの全段階を通じて、デジタルモデルを単一の、動的で、法的拘束力のある情報源として確立します。この変化は単に技術的なものではなく、考え方、組織、リーダーシップ、契約慣行の変革を必要とします。.

トータルBIMとは?

トータルBIMとは、次のような建設手法を指します:

- BIMモデルは契約上、法的拘束力があります。

- BIMモデルには、完全な生産志向の情報が含まれています。

- BIMモデルはプロジェクト情報の唯一の情報源です。

- 従来の2D図面の作成と使用を最小限に抑えます。

- すべてのステークホルダーは、デジタルモデルの中で無条件に働きます。

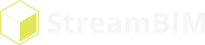

トータルBIMは、静的でバラバラの情報ソースではなく、クラウドベースのプラットフォームやモバイルBIMビューアーソフトウェアを通じて現場でアクセス可能な、単一の接続された情報環境を実現します。この環境では、すべてのプロジェクト参加者が情報を継続的に更新、フィルタリング、作成、再利用できます。.

従来のBIMでは不十分な理由

これまでのBIM導入は、繰り返し起こるいくつかの問題のために、しばしば苦戦を強いられてきました:

- BIMと2D図面の並行納品による不整合

- モデルが更新されなくなった場合のBIMへの信頼の喪失

- 現場担当者ではなく、主にエキスパート・ユーザー向けに設計されたソフトウェア

- オンサイトでのハードウェアアクセスの制限と不十分なトレーニング

- 相互運用性の課題と未解決の法的枠組み

その結果、いわゆる “BIM プロジェクト” でさえも、建設は従来、静的でつながりのない情報に依存してきました。トータルBIMは、動的なモデルベースの生産プロセスを導入することで、これらの欠点に対処します。.

トータルBIMの実践:ケーススタディからのエビデンス

スウェーデンとノルウェーのケーススタディに基づくチャルマース大学の研究は、トータルBIMが現場の建設実務を根本的に変えることを実証しています。.

重要な発見は、建設労働者はもはや図面を受け取るだけの受動的な存在ではないということです。代わりに、彼らはデジタル情報の積極的な作成者と消費者になります。モバイルデバイス上で最新の使いやすいBIMビューアーソフトウェアを使用することで、現場作業員は以下のことが可能になります:

- モデルで直接測定

- 関連情報のフィルタリングとクエリ

- BIMオブジェクトにリンクされた構造化データ、写真、コメントの追加

- 定義済みの図面に依存するのではなく、タスク固有のビューを生成

このダイナミックな相互作用により、BIMは設計成果物からライブ制作およびコミュニケーションプラットフォームへと変化します。.

統合されたコミュニケーションと情報の流れ

トータルBIMの最も大きなメリットの一つは、コミュニケーションの改善です。以前は電子メールや電話、孤立した文書でやり取りされていた情報が、モデル環境内で透明化され、追跡可能になり、アクセスできるようになります。.

調査したプロジェクトでは、BIMビューアアプリケーションは、視覚化ツールを超えて統合管理プラットフォームへと進化しました。情報提供依頼(RFI)、現場写真、測定、簡単な説明がモデルオブジェクトに直接リンクされました。これにより、処理時間が短縮され、状況認識が向上し、管理チームが建設進捗をよりよく監視できるようになりました。.

トータルBIM導入の成功要因

ケーススタディを通じて、いくつかの共通の成功要因が確認されました:

- 法的・契約的拘束力を持つ文書としてのBIM

図面を排除することで、曖昧さがなくなり、すべての利害関係者が同じ情報源に頼ることになります。. - 高品質で生産志向のBIM

モデルは、詳細で、構造化され、設計意図だけでなく、建設用に調整されていなければなりません。. - クラウドベースのモデル管理とモバイルアクセス

現場でのリアルタイムアクセスにより、BIMは常に更新され、信頼され、適切な状態に保たれます。. - パワフルかつユーザーフレンドリーなBIMビューアーソフトウェア

ツールは、測定、フィルタリング、情報作成を可能にし、専門家でないユーザーをサポートする必要があります。. - 強力なリーダーシップと経営陣のコミットメント

トータルBIMプロジェクトを成功させるには、部分的な採用ではなく、断固としたリーダーシップと「オールイン」戦略が必要です。.

ケーススタディの1つである、受賞歴のある 摂氏 スウェーデンのデベロッパー Vasakronan によるルンド大学キャンパス内の研究室兼オフィスビルは、これらの要素を例証するもので、詳細な BIM データを作成するための初期設計の労力が高まったにもかかわらず、納期通りに約 900 万クローネの予算を下回って完成しました。.

役割と責任の変化

トータル BIM は、建設プロジェクトにおける専門家の役割を根本的に変えます。設計者は、最終的な結果に対してより大きな影響力を得ながら、より早い意思決定にコミットしなければなりません。現場作業員や下請け業者は、施工性とデータ品質を確保するため、設計段階の早い段階で関与します。.

研究されたプロジェクトでは、構造化された複数ステップの品質保証プロセスにより、生産担当者がモデル開発に直接関与しています。このシフトは、現場作業員を静的な指示の受信者から、共有されたデジタル知識ベースへの貢献者に変えます。.

課題と将来への影響

トータルBIMは大きなメリットを実証していますが、課題も残っています。特にBIMが法的拘束力のある文書となるため、品質保証、公差管理、規制の枠組みに新たな要求が課されます。標準とガイドラインは、これらの新しいデジタルプラクティスをサポートするために進化する必要があります。.

今後、トータル BIM は建設現場のデジタル・ツインの基礎を築きます。チェックリストデータ、センサー入力、リアルタイムの進捗モニタリングの統合により、プロジェクトマネージャーと建設作業員の能力がさらに向上し、プロジェクトのライフサイクル全体を通じてデータ主導の意思決定が可能になります。.

デジタル建設の触媒としてのトータルBIM

Total BIMは、段階的なBIM導入にとどまらず、全体的、統合的、かつ生産に焦点を当てたデジタル建設手法へと移行します。図面を排除し、情報の流れを統一し、現場の担当者に権限を与えることで、トータルBIMは建設プロジェクトにおける長年の非効率に対処します。.

調査とケーススタディは、静的な 2D 図面はもはや必要なく、BIM がすべてのプロジェクトフェーズにわたって動的な単一情報源として機能することを示しています。移行には強力なリーダーシップと発想の転換が必要ですが、トータル BIM は、エラーを削減し、手戻りを最小限に抑え、デジタル建設の価値を最大限に引き出す、将来の建設に適した方法となるかもしれません。.