This is a case study prepared by StreamBIM Japan, which shows how the StreamBIM collaboration platform is being used in a Japanese context.

Key Points

The hospital project required highly specialized input from medical staff and facility managers, demanding extensive coordination and consensus-building.

Multiple discipline-specific public contracts increased complexity in scope coordination and change management.

StreamBIM was introduced early to centralize information, support collaboration, and promote paperless workflows.

Contractors, many new to Digital Construction and CDE tools, adopted StreamBIM gradually through training sessions.

3D models and meeting materials were shared on StreamBIM, improving access, transparency, and efficiency.

Hand-annotated 2D drawings were uploaded and converted into action items, enabling clear visualization of progress via checklists.

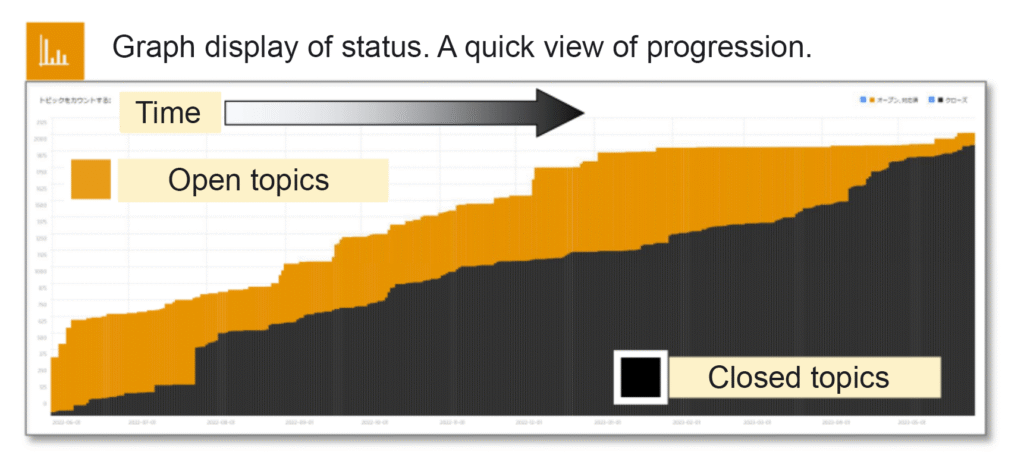

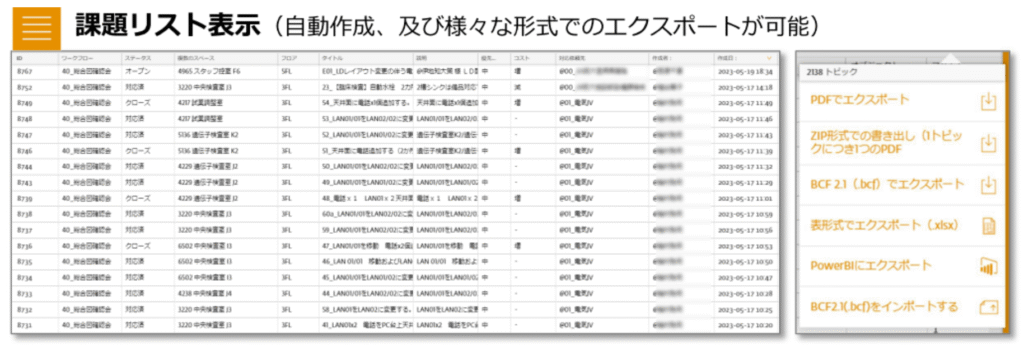

StreamBIM’s capture function digitized issue management, allowing real-time task tracking, deadline control, and centralized dashboards.

Adoption of digital workflows fostered proactive problem-solving and improved team motivation.

Integration with budget management improved transparency, sped up quotation-related processes, and reduced the risk of oversight.

Post-completion, accumulated data was used with AI analysis, demonstrating future potential for extending StreamBIM usage across design, construction, and maintenance phases to advance industry-wide digital transformation.

3D View, displaying IFC and point cloud data

A defining aspect of this project—the construction of a general hospital—was the need for distinct functional requirements and equipment specifications across departments and rooms. As a result, it was essential to collect detailed input from medical staff and facility managers, who would ultimately use the facility, throughout the design and construction stages. This process also required thorough consensus-building during the preparation of the comprehensive drawings following the commencement of works.

In addition, since this was a public works contract rather than a typical lump-sum agreement, separate contracts were executed for each discipline: construction supervision, building works, mechanical works, electrical works, and medical equipment. Consequently, multiple contractors were directly engaged by the client, making the coordination of work scopes and the management of change requests across disciplines inherently complex.

The involvement of stakeholders from various specialized fields further emphasized the need for close collaboration and consensus-building. To address these challenges, the use of the Common Data Environment (CDE) platform StreamBIM was proposed, leading to the establishment of a formal contract between the client and the contractors.

Promoting Paperless Production: Streamlining Information Sharing with StreamBIM

The use of StreamBIM had been explicitly proposed by the construction contractors during the technical proposal stage, eliminating the need to deliberate over tool selection at the start of the project. However, for many contractors, this was their first experience using a Common Data Environment (CDE) platform, requiring them to adapt to new workflows and operational practices. Implementation began gradually through study sessions focused on basic functions. The 3D model developed during the basic design phase was uploaded to StreamBIM, creating an environment that allowed stakeholders to view and interact with the model directly on their own devices. In addition, the procedure for weekly coordination meetings was improved by storing materials—previously distributed in advance via email—within StreamBIM, streamlining access and information sharing.

Handwritten information were also added to the task list and confirmed at the follow-up meetings.

The label search function (label name: “Same-day Meeting Materials”) enables immediate access to required documents, significantly advancing information-sharing efficiency and paperless operations.

Visualisation of Progress: Streamlining Site Operations through the Integration of 2D Drawings and StreamBIM

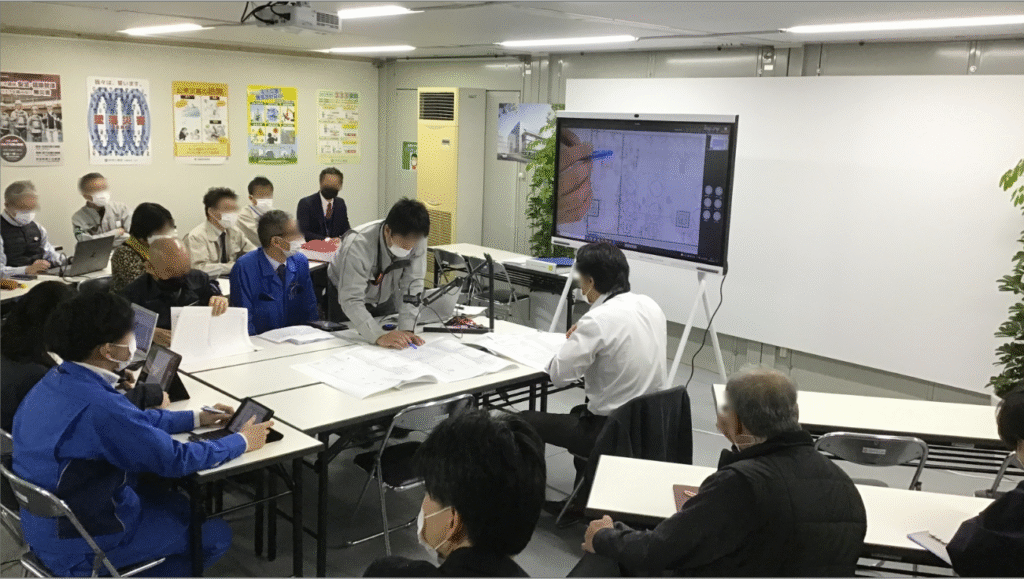

In Japan, verification using 2D drawings remains the prevailing practice. Accordingly, the BIM model in this project was employed as supplementary reference material. Detailed floor plans and level-specific layouts were reviewed during comprehensive drawing verification meetings, where stakeholder requests were gathered in real time and recorded directly in StreamBIM. By the conclusion of each meeting, the responsible party for addressing each issue was clearly identified. Requests were annotated by hand on the 2D drawings, which were then photographed, uploaded to StreamBIM, and registered as action items. For rooms where verification had been completed, StreamBIM’s checklist function was used to share information linked to the corresponding spatial data within the BIM model. This allowed progress to be easily visualized, with completed items displayed in green and pending items in red.

Checklist Function 2D Screen

Can be overlaid on any PDF plan

The process involved annotating 2D drawings by hand, uploading the annotated images to StreamBIM, and creating corresponding task entries. For rooms where verification had been completed, StreamBIM’s checklist function was used to share information linked to the spatial data within the BIM model. Progress was effectively visualized, with completed items shown in green and outstanding items in red, enabling clear and intuitive tracking of the verification status.

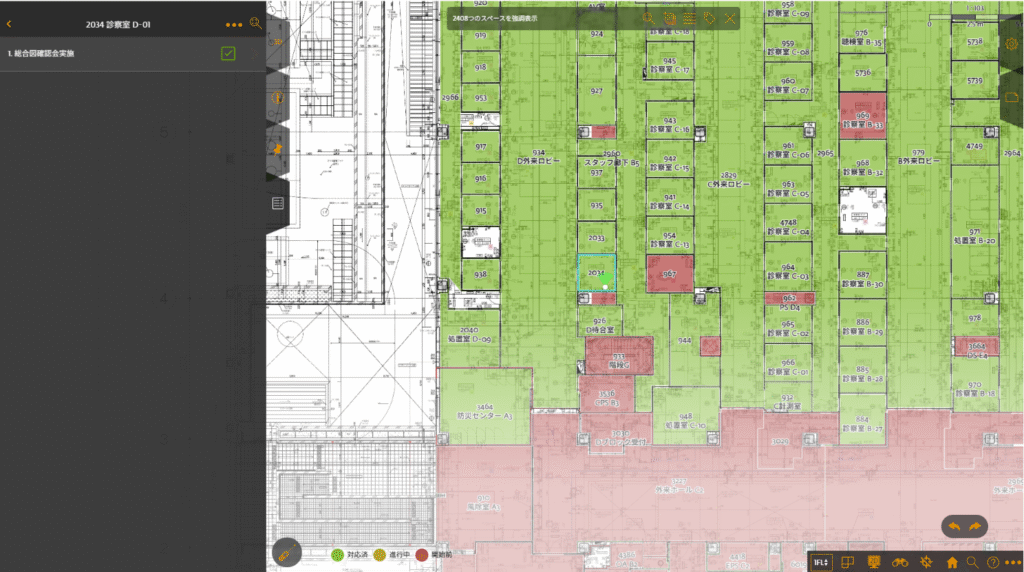

The Evolution of Task Management: Real-Time Sharing and Progress Visualisation

Even when the requirements from medical staff and facility managers had been confirmed during the design phase and incorporated into the design documents, numerous change requests still emerged during reviews of the comprehensive drawings prepared after construction began. These requests often stemmed from more specific and practical usage scenarios that became apparent at that stage. Previously, the responsible personnel managed these processes manually—storing materials on a shared server, preparing documents, sharing updates via CC emails, and individually creating and maintaining issue management sheets.

Previously, progress updates for tasks had to be entered manually by the responsible personnel, often resulting in delays and difficulty obtaining up-to-date information. The introduction of StreamBIM’s capture function effectively resolved this issue. Relevant team members learned the operating procedures and began creating digital tickets for each task, assigning responsible parties and attaching handwritten documents as images. These registered issues were compiled into a centralized database, allowing progress status, deadlines, responsible personnel, and issue counts to be visualized and shared efficiently through the dashboard at a glance.

The personnel responsible for each issue adopted a workflow in which they addressed tasks in order of approaching deadlines while regularly updating and sharing the resolution status with the initiator. This system encouraged stakeholders to take a proactive approach to issue resolution, ultimately leading to the establishment of an on-site rule: “All issues should, in principle, be resolved within two months.” The client’s project manager noted, “It’s rather enjoyable to see stakeholders tackling issues competitively, almost like a cultural festival,” highlighting how the implementation of StreamBIM fostered a stronger sense of collaboration and motivation among team members on site.

Integration with Budget Management: StreamBIM's Enhancement of Operational Efficiency and Transparency

All issues were consolidated within the database, allowing budget managers to easily identify cases requiring financial settlement based on the accumulated issue data. Furthermore, when resubmitting quotations, sharing the URLs of previously approved issues directly through StreamBIM enabled swift and accurate reference to past cases. In the past, collecting and organizing such information required sorting through large volumes of emails and dispersed documents—a process that demanded significant effort and carried a high risk of oversight. This new operational approach has established a highly transparent workflow for both clients and contractors, significantly improving the reliability and efficiency of project management.

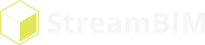

At the post-completion feedback session

Summary and Future Outlook: The Future of Construction DX Built by StreamBIM

During the initial training sessions for StreamBIM implementation, participants were seen navigating the 3D interface intuitively—even before formal instruction—demonstrating the platform’s high level of user-friendliness. What began with casual curiosity—remarks such as “It looks convenient, shall we give it a try?” or “Let’s just test it out”—quickly evolved into recognition of StreamBIM as an indispensable on-site system.

In the post-completion feedback sessions, data accumulated through the capture function was utilized in conjunction with AI-driven analysis. Although this use had not been initially envisioned, it showcased the system’s flexibility and the broader potential of information stored within StreamBIM to inform future construction projects. Looking ahead, expanding the use of such data beyond construction sites to include the design and maintenance phases is expected to further accelerate digital transformation (DX) across the entire construction industry.